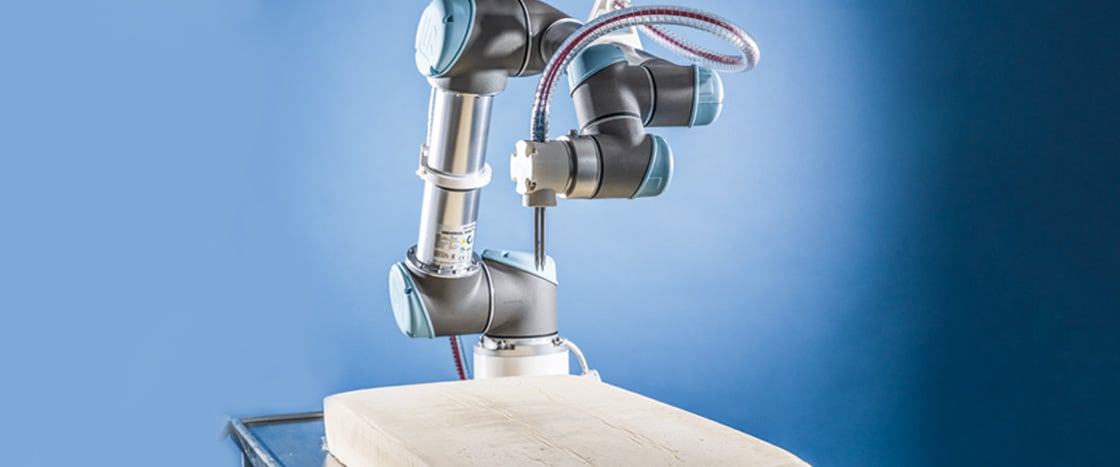

When dairies make cheese, workers normally taste samples of the finished product to test its taste, texture, and smell. Low-quality batches don’t make the cut. To improve the process, scientists in Denmark recently designed a robot to check cheese quality as it’s being made.

Making cheese starts with milk. Tiny organisms called bacteria are used to curdle the milk, or make lumps in it. Later, salt and spices are added for flavor. The robot tracks ingredients during the process using infrared light, which is invisible to the human eye. The cheese absorbs some of the light, and the rest bounces back to the robot. This gives information about fats, proteins, and other nutrients. If anything is wrong, workers can quickly fix the recipe. Thanks to the bot, dairies won’t need to rely on tasters alone.